We’re back with more tips from Michele Rodriguez to help ensure success with your print projects. This is the second in a two-part series. If you missed the first set of basic tips, you can read them here. Michele, owner and principal designer at Incognito Graphic Design, developed her expertise in designing for commercial printing over the course of a decade at Publication Printers while providing training and support to our customers in file prep and best commercial print practices, among other things.

Commercial printing is a science, with multiple variables that affect the outcome of the project. As a designer, how you prep and supply your files to the printer will determine the outcome of your final project. Here are some common things to keep in mind along the way.

Color Calibration of Your Monitor and Simulation Profiles

All Adobe programs have simulation profiles available to simulate the printing conditions, paper, and ink for your project. This will aid you in making color adjustments to photos and getting a feel for how your project may look once printed. Of course, looking through light on a monitor will be different than ink on paper, but if your monitor is calibrated and the profiles are used correctly, you should have a good representation of what the output will be.

To accomplish this, first you will need to calibrate your monitor using a calibration device and target. PPC uses and recommends the x rite i1 Display Pro device. They can provide the settings and a printed target from their Epson proofer that will assist you in getting your monitor calibrated. Please contact your account manager for further information on this process.

There are different brightness levels in the paper your project runs on. Magazines are rarely printed on bright white stock. While bright white is available, it is generally more expensive than less bright stock. Therefore, many magazines are printed on a #3 stock, which has a slight gray tint to it. If you take a piece of copy paper and put it on a non-printed area, you will see the difference. This is where the simulation profiles will help you. When you choose the correct color profile and the “simulate ink & paper” option, Adobe will apply a filter to your screen to show you how the paper may affect the final look of your layout. This does not change the file but gives you a visual representation so you can make color adjustments to compensate.

If you would like further information about how to utilize simulation profiles, please contact your account manager, who will put you in touch with the prepress department.

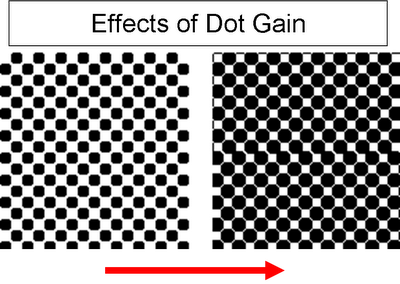

Ink Density & Gain On Press

Ink density is determined by adding your CMYK values together. Registration black is 100% of CMYK resulting in an ink density of 400%. Generally, you will want to keep your ink density around 300% total area coverage for coated stock and about 280% TAC for uncoated stock. This is because as the ink hits the paper, it spreads and will gain, or cover more area. This results in a more saturated and dense color. The amount of gain will vary but is around 8-10% on coated stock and 10-12% on uncoated stocks. Please note that there are varying levels of uncoated and coated stock so you will want to discuss this further with the prepress department for your specific project.

This explains why you may have noticed some of your light screen values come out darker or shift in color on the final piece and why images that are already a little dark may print even heavier on paper. If this is the case, you can compensate for these gains by adjusting your builds and images to be about 8-10% lighter than what you would like the end result to be.

Screen Values and Light builds

Let’s start with gray. While there are warm, cool, and neutral grays, whenever possible, for large areas of coverage or multiple use of gray type or elements across pages, I recommend going with a screen value of black only for gray screens. There are variations on press of the CMYK inks, so if you have CMY values in your black screens, although the build the is neutral in your file, if the pressman has to adjust the CMY to accommodate other images or elements on the page, your once neutral build of gray could turn warm or cool or have a tint of pink in it due to the slightest adjustment on press of those other colors. The same is true for light builds of neutral colors such as beige, tan, yellow, green or the like. Using these builds over large areas or across multiple pages on a form can present a challenge to the pressman and keeping the color consistent across all of them. We’ll discuss the press forms and adjustments next, so this makes more sense.

Press Forms and Inline Pages

When a publication runs on press, they are likely to run on forms with 8, 12, 16, 24 or 32 pages. The forms are paginated based on the binding style and page count. This means that you will not be running consecutive pages next to or in line with one another. If you have a catalog with product images and different colored bars on the face to designate sections, oftentimes the pressman will have to decide if they want the bars to remain consistent in color or adjust the photos to look consistent because rarely can you accomplish both and keep it consistent throughout the entire run.

The same is true when running an ad or layout with heavy black coverage and a dark image in line with a page that has no coverage and a bright image and neutral tan background. If the heavy ad is lightened, the brighter ad will be affected. This can present a challenge on press. Try to adjust your images and layouts to be consistent throughout so minimal adjustments to the ink densities need to be made on press.

Please reach out to [email protected] if you’re interested in remote or onsite training.